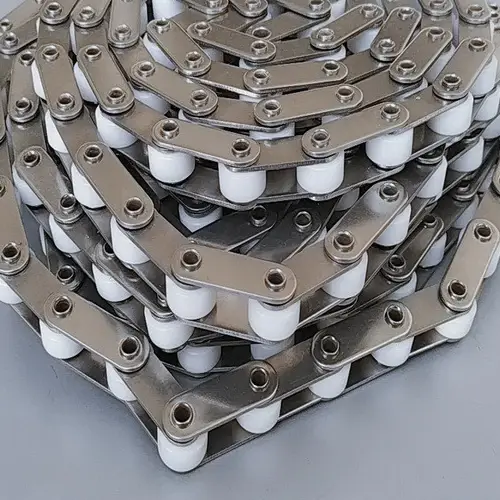

China OEM Factory Price OEM ODM Stainless Steel Material Carbon Steel Industrial Agriculture Roller Chain Hollow Pin Chain

Product Description

Our hollow pin chains are made of high-quality stainless steel and carbon steel materials. These chains are perfect for industrial and agricultural applications, delivering maximum performance in demanding environments.

Our chains are available in a variety of sizes and specifications, meeting your multifarious demands. Our company adheres to the management principles of "quality first, customer first and credit-based", always doing our best to satisfy potential needs of customers.

We offer a wide range of industrial products, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. Our commitment to high-quality products, preferential prices, and considerate services makes us a reliable partner for all your industrial needs.

FAQs

What materials are the hollow pin chains made of?

Our hollow pin chains are made of high-quality stainless steel and carbon steel materials, ensuring maximum durability and performance in demanding environments.

What sizes are the chains available in?

Our chains are available in a variety of sizes and specifications to meet your multifarious demands. Please contact us for more information on specific sizes and customizations.

What industries are the chains suitable for?

Our hollow pin chains are suitable for a wide range of industrial and agricultural applications, delivering maximum performance in demanding environments.

Can I customize the chains based on my specific needs?

Yes, we offer customization services for all our products, including hollow pin chains. Please contact us with your specific requirements, and our team will be happy to assist you.

What other products does your company offer?

In addition to hollow pin chains, we offer a wide range of industrial products, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. Please visit our website for more information on our full product range.

All content on this page is from the Internet. It is provided only as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks of the content. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

Performance Characteristics of Hollow Pin Chain

Hollow pin chain is a type of roller chain that is used in various industries to transmit power. This chain is designed with hollow pins that make it lighter in weight and more flexible than the standard roller chain. The following are some of the performance characteristics of the hollow pin chain:

High Tensile Strength

The hollow pin chain has a high tensile strength, which makes it ideal for use in heavy-duty applications. This chain can withstand high loads and forces without stretching or breaking.

Flexibility

The hollow pin chain is more flexible than the standard roller chain. This makes it suitable for use in applications where the chain needs to bend around corners or over pulleys.

Easy Maintenance

The hollow pin chain requires minimal maintenance and is easy to clean. This makes it ideal for use in environments where cleanliness is important, such as the food processing industry.

Types and Characteristics of Hollow Pin Chain

There are various types of hollow pin chain available on the market, each with its own characteristics. Some of the most common types of hollow pin chain include:

Standard Hollow Pin Chain

This is the most common type of hollow pin chain. It is designed with a standard pin size and pitch and is suitable for use in most applications.

Double Pitch Hollow Pin Chain

This chain has a longer pitch than the standard hollow pin chain. This makes it suitable for use in applications where a longer pitch is required, such as conveyor systems.

Heavy-Duty Hollow Pin Chain

This chain is designed for heavy-duty applications and has a higher tensile strength than the standard hollow pin chain. It is suitable for use in applications where high loads and forces are present.

Advantages of Hollow Pin Chain Made of Different Materials

Hollow pin chain can be made from a variety of materials, each with its own advantages. Some of the most common materials used to make hollow pin chain include:

Stainless Steel

Stainless steel hollow pin chain is resistant to corrosion and is suitable for use in environments where high levels of cleanliness are required.

Carbon Steel

Carbon steel hollow pin chain is strong and durable, making it ideal for use in heavy-duty applications.

Plastic

Plastic hollow pin chain is lightweight and resistant to corrosion, making it suitable for use in applications where cleanliness is important.

Application of Hollow Pin Chain

Hollow pin chain is used in various industries, including Conveyor Systems, Food Processing, Agricultural Machinery, Automotive Industry, Textile Industry, and many others. Its flexibility, high tensile strength, and easy maintenance make it ideal for use in these industries.

Future Development Trends and Opportunities of Hollow Pin Chain Products

The future of hollow pin chain products looks bright, with many opportunities for growth and development. As industries continue to evolve and demand for high-quality products continues to increase, there will be a need for innovative and high-performance hollow pin chain products.

How to Choose a Suitable Hollow Pin Chain

Choosing the right hollow pin chain for your application is important to ensure optimal performance and longevity. The following are some factors to consider when choosing a suitable hollow pin chain:

Determine Application Requirements

Consider the load, speed, and environment in which the chain will be used. This will help you determine the type and material of chain that will best suit your application.

Identify the Type of Chain

Choose the type of chain that is best suited for your application. Consider factors such as pitch, strength, and flexibility.

Select the Chain Material

Choose a chain material that is suitable for your application. Consider factors such as corrosion resistance, strength, and weight.

Consider the Chain Dimensions

Choose a chain with the appropriate dimensions for your application. Consider factors such as pitch, roller diameter, and plate thickness.

Check Compatibility with Sprockets

Ensure that the chain you choose is compatible with the sprockets in your application. Consider factors such as tooth profile, pitch, and bore diameter.

Summary

Hollow pin chain is a highly versatile and flexible type of roller chain that is used in various industries. Its performance characteristics, types and characteristics, advantages of different materials, application, future development trends and opportunities, and how to choose a suitable hollow pin chain have been discussed in this article. It is important to choose the right hollow pin chain for your application to ensure optimal performance and longevity.

Author: Dream